BrewPi Soldering Guide

This page will give you a step by step guide to soldering your BrewPi Arduino Shield RevC. If you still need instructions for RevA, take a look at the old page. I have soldered quite a lot of shields and this is the order which I think is the easiest. It is best to read this guide while soldering to make sure you don’t forget something, so here is a QR code to bring it up on your smartphone:

So lets get started! You will need:

- A BrewPi Arduino shield kit

- A soldering iron

- A tip cleaner (I recommend golden curl over wet sponge)

- Solder

- A side cutter

- Pliers

From now on this guide will be nothing but pictures with a description! I think pictures are much more helpful and prevent errors so this guide has a lot of pictures. To help with opening the page on portable devices it is broken up into 5 pages, 15 images per page.

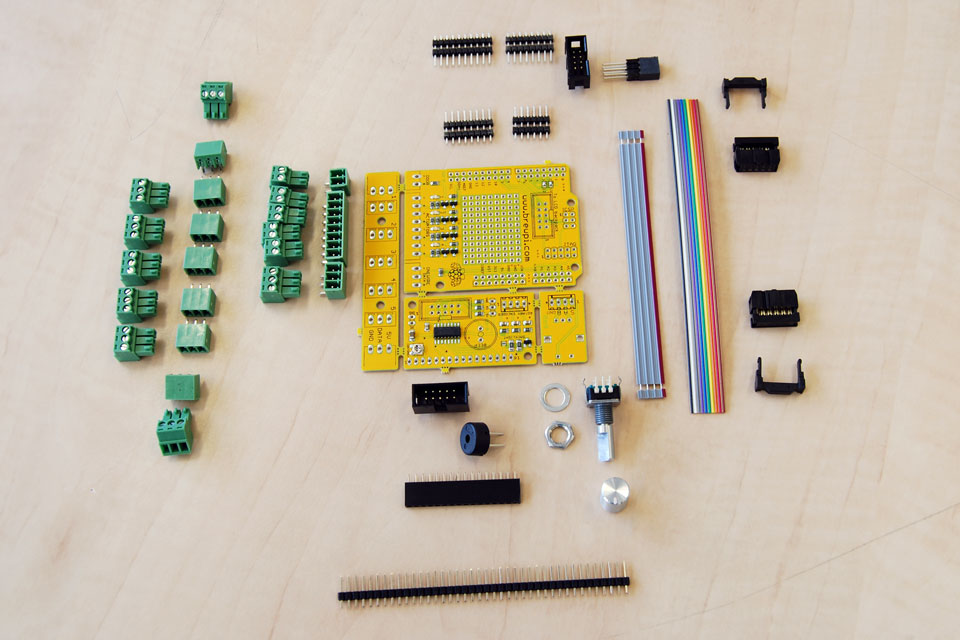

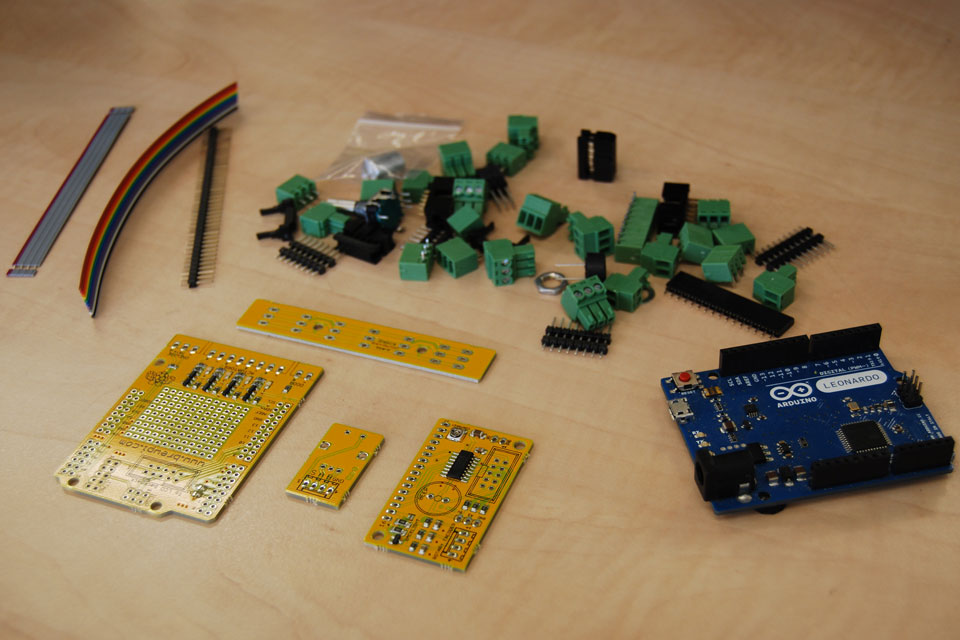

This is what you bought from the shop: a 4-part PCB with SMT components soldered and a bag of through hole parts. Go ahead and empty the bag on your desk.

Also in the picture: golden curl tip cleaner (highly recommended!) and the needed side cutter and pliers.

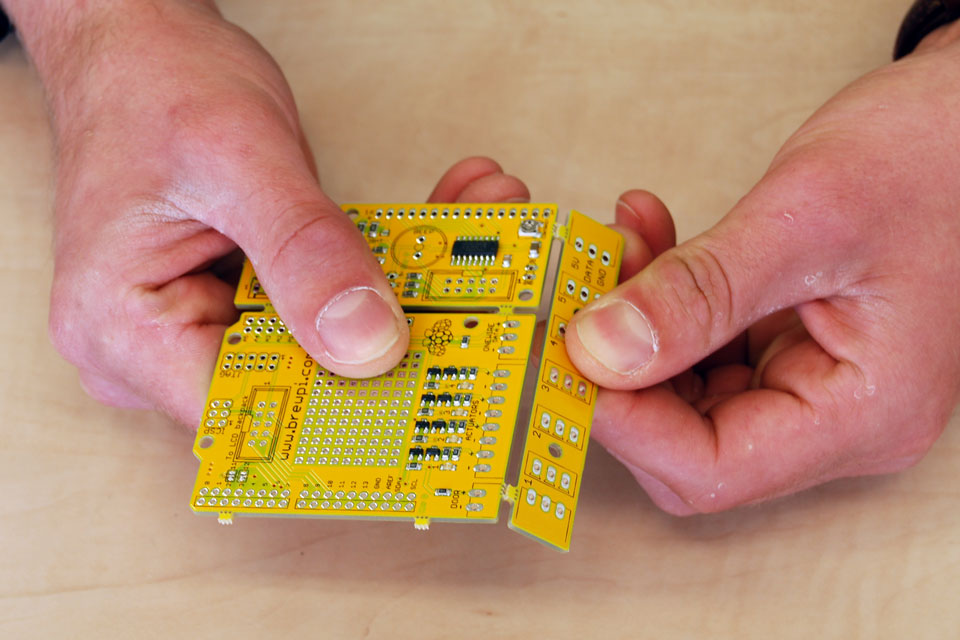

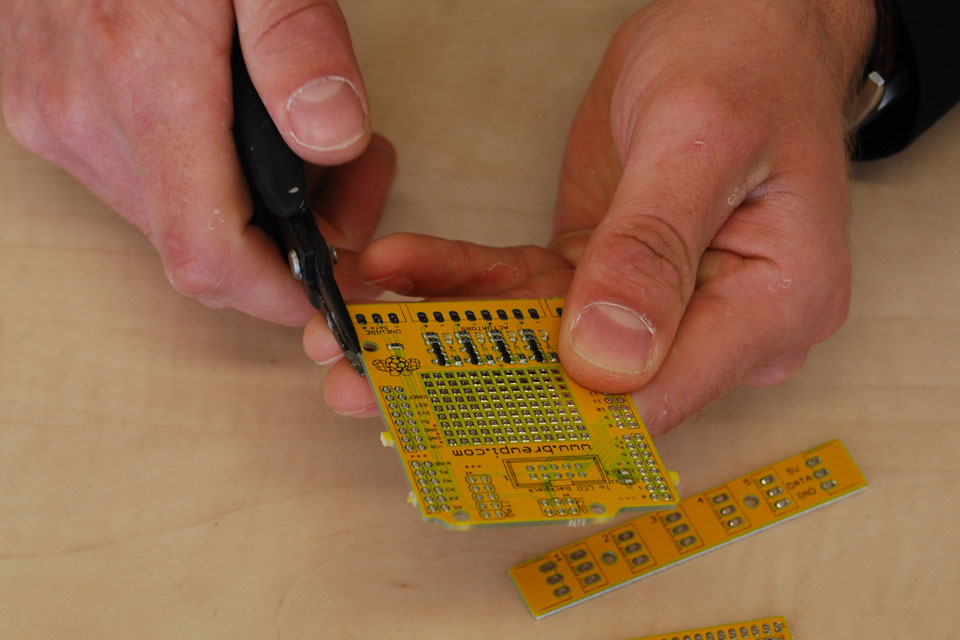

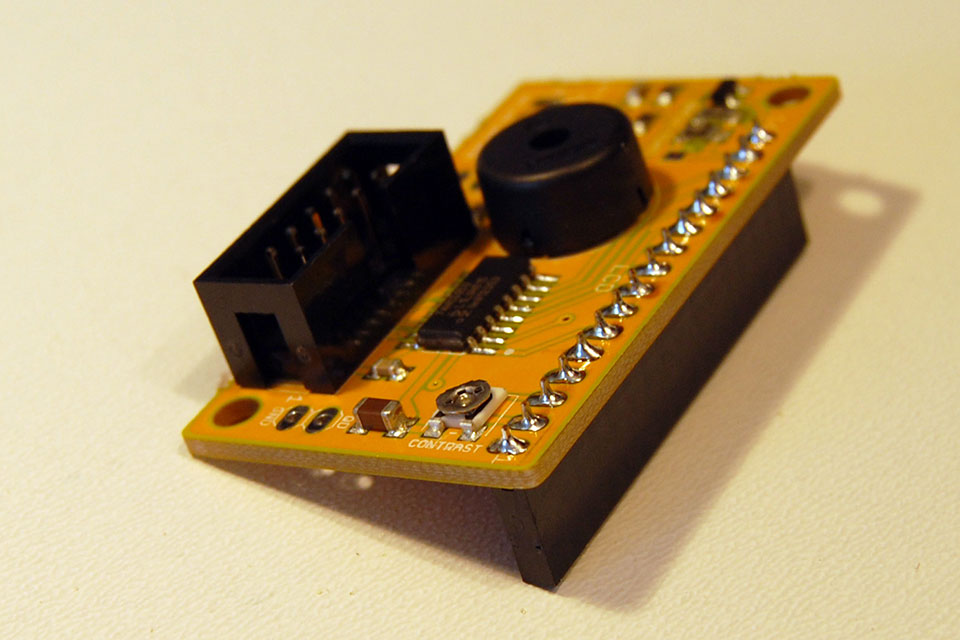

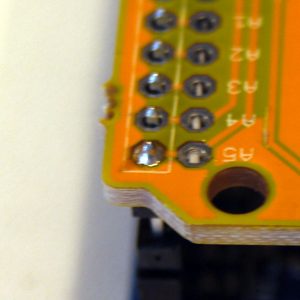

You now have 4 separate boards: the main shield, the LCD backpack, the rotary encoder breakout board and the OneWire distribution board. Time to start soldering!

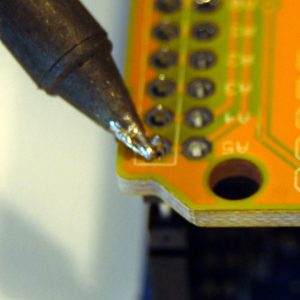

A quick primer on soldering… Step 1: press the tip of your soldering iron against both the pad and the pin.

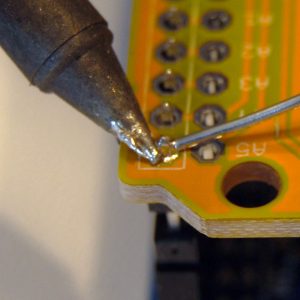

Step 2: Add solder. Do not put solder on your tip first! The flux will evaporate before you start. Push the solder against the pad/pin.

Step 3: Wait until the solder flows to the entire pad. You can add a little more solder to help if it doesn’t flow nicely, because this also adds new flux.

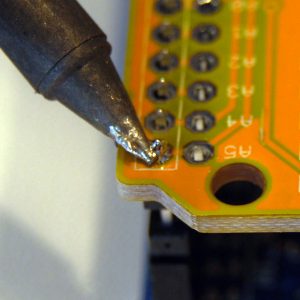

The result should be a shiny concave joint. If the joint is dull or pointy, the flux has evaporated. Work quicker or lower your soldering temperature.